You might not be familiar with quartz as a name for a surface, though it’s posible that you’ve seen hundreds of countertops made of this material and didn’t realize about it. This material is often referred to in the industry as quartz, but the name engineered Stone gives you a better idea of what it is.

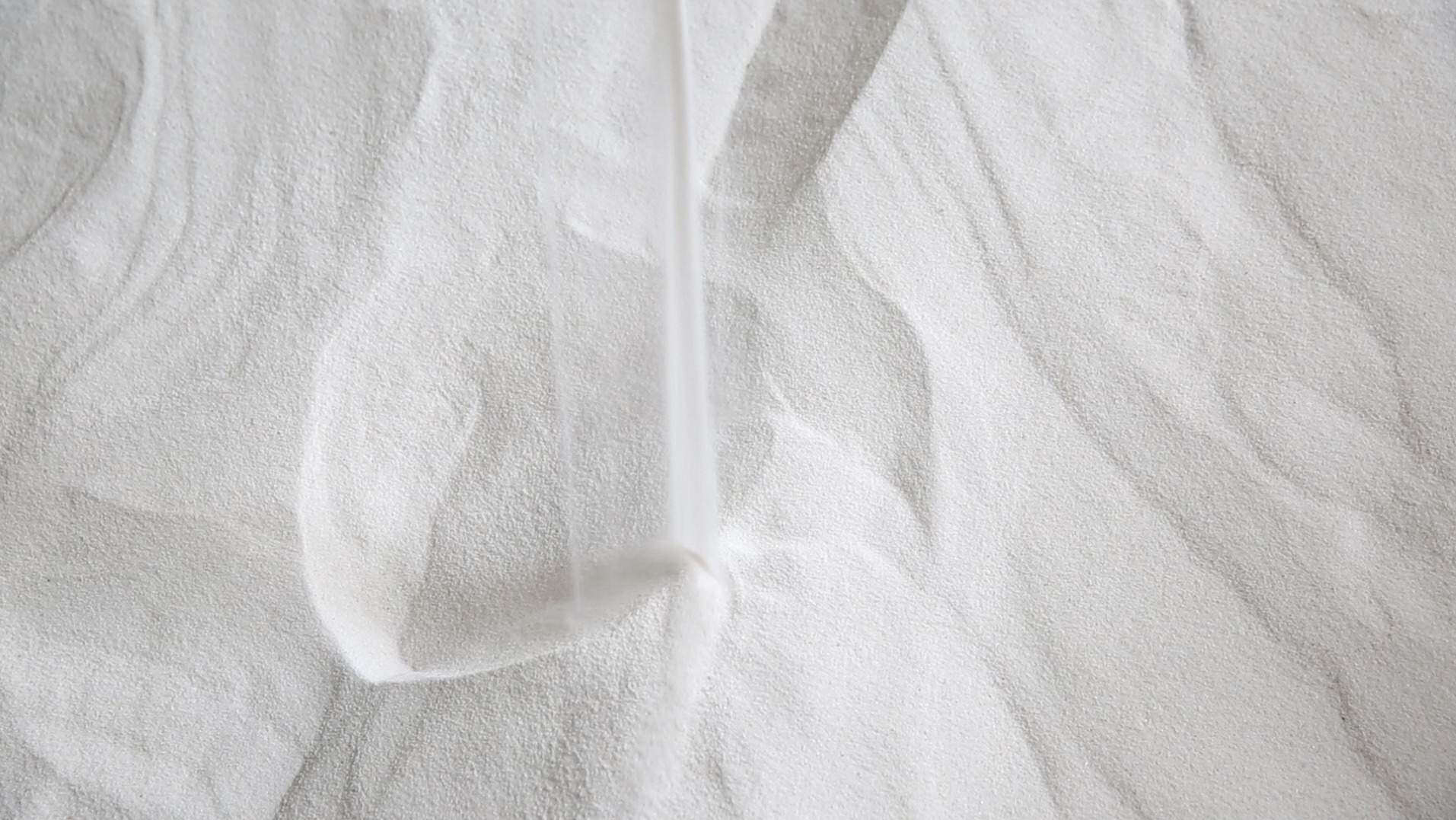

Unlike natural stone countertops that are cut from pure granite, marble or sandstone, engineered quartz counters are made from quartz crystals held together with resins and pigments. They have similar appeareance to natural stone, but they possess benefits not available with natural surfaces.

Before the benefits, what it is engineered quartz?

Engineered quartz is composed of up to 95% natural quartz in which pigments and resins are added and diluted in a process called “engineered stone” in which all these elements are compacted by vacuum vibrocompression obtaining a material with high resistance and decorative qualities.

Quartz is one of the most abundant minerals on Earth, and it comes in a very wide range of types of qualities. The Mohs scale, which compares the hardness of minerals depending on their capacity to score the surface of softer minerals, places quartz in position number 7, under the hardest elements: diamonds (10), corundum (sapphire) (9), and topaz (8).

Quartz is one of the most abundant minerals on Earth, and it comes in a very wide range of types of qualities. The Mohs scale, which compares the hardness of minerals depending on their capacity to score the surface of softer minerals, places quartz in position number 7, under the hardest elements: diamonds (10), corundum (sapphire) (9), and topaz (8).

What makes engineered quartz so convenient?

Hardness: almost unbreakable!

Quartz is extremely hard and really convenient for a good work surface. It’s 95% composed of natural minerals in contrat with other solid surfaces which only use a low percentage and about a 33% inorganic binding resins. Engineered quartz won’t crack as easily as granite or slate does. These surfaces are resistant to scratches and cuts, though it’s still recommended you use a cutting board on top of them.

Forget about maintenance

Its almost zero porosity, prevents the absorption of water or other liquid, making clean up easier and more effective. Consequently engineered quartz does not need antibacterial chemicals, since the absence of pores prevents bacteria acting as a natural bacteriostatic, making it highly recommended for household surfaces that come into contact with fatty foods or cleaning products; such as countertops, walls and doors in kitchens and bathrooms.

Surfaces won’t stain

Natural stone is susceptible to staining from oil, wine, juice and other substances if not properly sealed or if the sealant wears off. Engineered countertops stand up to these materials very well. They’ll look better longer than their granite, marble or sandstone counterparts.

Wide range of options!

There are a lot of designs, colors, textures and formats to choose from so you will just have to decide what suits your home better.

COMPAC also includes BIO resins

The Spanish engineered quartz manufacturer, COMPAC, also adds BIO resins during the production processes. Thanks to this COMPAC has created a new quartz product with superior physical, mechanical and decorative features and mores respectful to the environment.

A good R + D + I department job has made COMPAC to achieve a technologically advanced product, increasing its resistance to abrasion, UV and with lower internal stresses.

Read more about COMPAC and its products in the website and visit our blog to find the latest trends in design, decor and architecture.